Hydraulic Hole Punching – Fabricating Switchboards

Designing and building an electrical switchboard isn’t always straightforward. There are components, such as cables, metal components and plates, that need to meet specific measurements. You also have to take account of how external and internal factors can affect the switchboard.

What are the attributes of a smartly built switchboard that meets cost, delivery and quality targets? Here are three factors a switchboard builder will immediately consider.

Optimal Design of Cable Entry Point

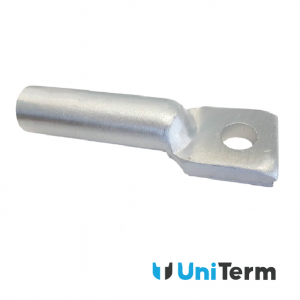

As a junction of incoming and outgoing electricity, a switchboard will need to accommodate numerous cables and busbars. Punching holes and making cut-outs on metal enclosures or switchboard doors provide a route for these different cables to connect. If any of these entry points can’t fit the cables or have sharp edges that can damage cables, switchboard integrity will be compromised. This will necessitate the removal or deburring of the excess material.

The electrician has to have the right tools that can ensure high-quality workmanship that allows him to create the switchboard cleanly and efficiently. An electrician’s hydraulic hole punch, which makes an accurately-sized hole right through metal is a much cleaner and efficient alternative to a hole saw.

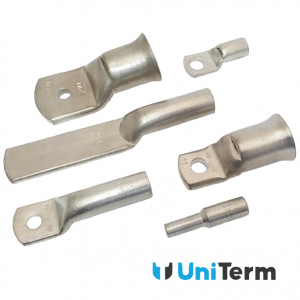

The hole punches are used on switchboards, Metal panels, Stainless Steel Sheet Metal and Plastics. No filing or de-burring is required and the punching of the hole is quick and easy. Our hole punches are excellent for using in tight and difficult spaces. UTTCO also offers square, rectangular and other shape punches.

- Conduits

- Conduit Fittings

- Cable-glands

- Bushes

- Switches

- Pilot Lights

- Volt Meters

- Multipoles

- All Need Holes

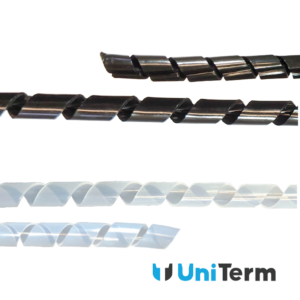

Can Adapt to Changes in Internal and External Temperature

Temperature problems can arise internally within the switchboard when the ambient temperature outside of the switchboard significantly increases. If the switchboard your building is subject to ambient temperatures that can get extremely hot, forced cooling with fans and air conditioning may solve the issue. Square punch & Dies can help create holes for ventilation.Takes Into Consideration the Surrounding Environment

Before building the panel, you have to inspect where it will be installed — whether it’s fixed to a wall or mounted on a piece of machinery. You don’t want the internal cables and the switchgear to be vulnerable to the elements. To that end, switchboard builders will assess an area to ascertain:- Is the area too exposed to dust particles?

- Is the area too exposed to direct sunlight?

- Is there a potential threat of water ingress?

There are, of course, other factors and best practices to consider when building electrical switchboards. But a great starting point is making sure you have the tools that empower you to do your work cleanly and more productively.

Universal Tools & Termination can provide you with high-end electrical tools, wherever you are in Australia. Call us on 1300 024 858 or send us a quick email at sales@uttco.com.au to find what you need to do your best.